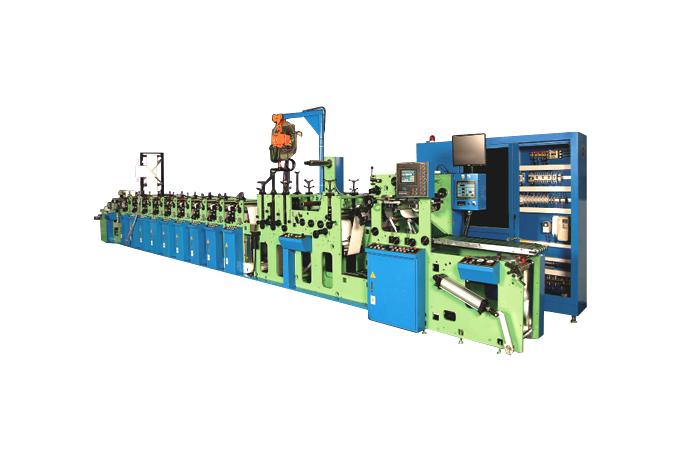

Flexo Rotary Printing Machine (for special thermal paper, sticker, label and package) Successful self-development and practical use! Low environmental load. (water ink used)

High productivity, easy operation and high-quality printing effect!

High-precision control and multifunctional printing!

Specification of Flexo Printing Machine

|

Flexo Printing Machine |

1-13 Colors (Optional) |

|

Sheet Thickness |

40g~300g |

|

Printing Width |

230mm 330mm 430mm 530mm (Optional) |

|

Max. Sheet Diameter |

1,270mm (50″) |

|

Max. Working Speed |

200m/min |

|

Folding Sheet Width |

5.5″~18″ |

|

Electric Power |

AC. DC. 15㎾~37㎾ |

Option Items

|

Automatic Feeding Tension System |

Web Guide Unit |

|

Hot-Air Drying System |

Sheet Cutting Machine |

|

U.V Drying System |

Print Searching System (Optional) |

|

Reverse Printing Unit (X belt) |

Automatic Alignment System (Optional) |

|

Rotary Die-Cut |

Paper Folding Section (Optional) |

|

Anilox |

Automatic Ink Rotating Pump (Optional) |

|

Wastepaper Winder |

Ink Jet Installation (Barcode, Numbering) |

|

Textile Joint Table |

Paper Folding Section

- Folding crank enables to adjust folding width.

- Marking device enables marking on every page set.

- The velocity of conveyor belt can be varied by electric inverter system.

- Forward or backward movement can be adjusted by gear box even during paper folding.

- The height of conveyor can be adjusted.

- Operation is easy regardless of sheet thickness owing to automatic high-speed folding.

- Free vertical sewing is possible.

- 3-width folding is possible

Electric Operation Section

Electric Operation Section contains high-tech control panels suit to standard proportions, which anyone can easily operate. Also it includes all control units and automatic devices. PLC installed by each part helps users operate the machine easily.

It is easy to operate by touch panel.

Automatic pin control system

Feeding Section

- Textile joint table unit

- Paper feeding can be stabilized by powder brake control.

- Defect shaft prevents paper wrinkles by sensor.

- Natural air cooling system is selected as standard for water saving and user’s convenience. Max. sheet diameter is 1,270Ø.

- Paper is set by one touch for high working efficiency.

- Feeding side ray can move by ±25mm from all sides.

- Capacity of powder brake is 10-20k depending on printing grade.

- Web guide is installed to prevent textile shaking and supply paper stably.

- H guide is installable.

Offset Printing Section

- Anilow is detachable.

- Auto Alignment System (Optional)

- Doctor Knife Unit

- Automatic Ink Feeding Pump

- U.V Flexo ink is used.

- Printing pin can be adjusted 360° by forward or backward movement even during printing.

- Right and left of print can be adjusted up to ±10mm.

- X-belt can be installed by option.

- Hot-air drying system

- U.V drying system

- Water ink

- Photosensitive resin board

Processing Section

- Wastepaper winder is installed.

- Two sewing machine press tubes enable the mass production of irregular sewing to improve working efficiency.

- Jump sewing is possible by option.

- Marginal forward and backward movement is possible.

- Sheeting is possible.

- Rotary lengthwise and crosswise sewing processing

- Slitter Rewinder

- Rotary die-cut is possible

Rewinding Section

|

Max. Sheet Width |

250mm 350mm 450mm 550mm (Optional) |

|

Sheet Thickness |

40g~250g |

|

Max. Sheet Diameter |

¢1,200mm |

|

Max. Working Speed |

200m/min |

|

Electric Power |

AC. 7.5㎾ |