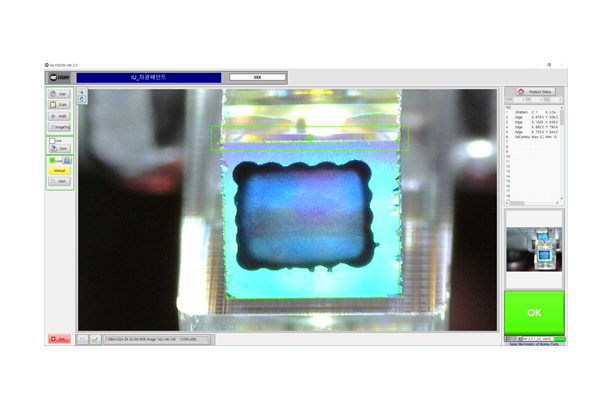

Point1 : PC environment vision inspection program that allows users to apply and edit image processing and various video processing technologies to meet specifications of the user

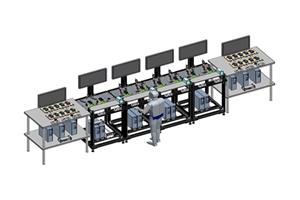

Point2 : For inspection purposes, various interface types including analog cameras are supported. Each type has a different throughput, cable length, power, I/O synchronization, CPU usage, and it is necessary to select the appropriate type according to the inspection facility structure and purpose

Additionally, it is important to select a camera for the purpose, and there are cameras of various types and prices depending on the number of pixels, color, speed of shooting, size, etc. We help you select a low-cost/high-efficiency optimal camera.

Speficiation

| Function | Processing | Example |

| Pattern Matching | X, Y, Angle, Score(Matching Rate) Measurement | Check parts, determine status |

| Edge | Boundary detection | Check parts & assembly status |

| Length | Horizontal, Vertical Distance Measurements | Position, apparent detection, distance measurement |

| Histogram | Measure the pixels of R, G, B, and Gray in 0-255 scales | Stain, print concentration check |

| 1D Barcode | Codeba, Code93, Code39, Code,128, EAN8, EAN13, MSI, Interleaved2of5, Phandomcode, RSS Limited, One-Dimensional Barcode recognition | Product Lot Manufacturing Information Management |

| 2D Barcode | Data Matrix, QR Code, PDF417, Two-dimensional barcode recognition | |

| OCR | Optical character recognition | Character recognition such as model name, expiration date, etc. |

| Circle | Measurement of the center coordinates (X,Y), radius (R) of a circle | Position of circular part, radius measurement |

| Color Pattern Matching | Measurement of Color Score(Matching Rate) | Color discriminating |

| Edge Contour | Contour detection | Surface inspection, chip testing |

| Blob | Surface foreign objects detection | Foreign objects inspection |

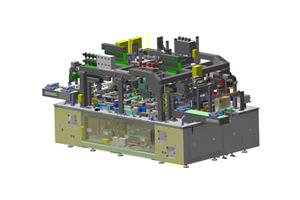

Practical Application Cases

[Status] Determining whether parts are inserted or missing

Requested

PWA area, Manual insert parts : Check for missing inserts

Actions

Using a library of NI machine vision algorithms that can detect the shape, location, and angle of a specific pattern contained in ez-VISION, not only missing inserts but also reverse inserts and misinsertions of the product

Actual photos

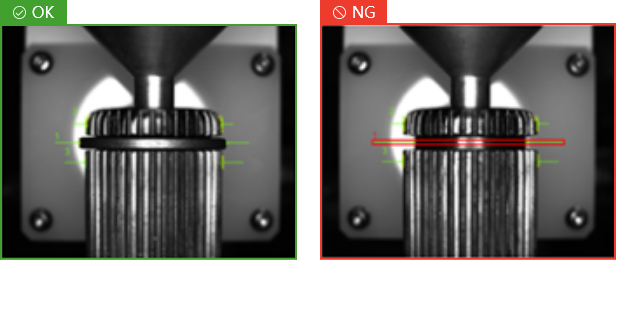

[Status/Position] Checking the engagement of ring parts

Requested

Check whether the ring is assembled or not, it's assembled in the right position, and it's double-assembled.

Actions

Measure the length of the product's width depending on whether the ring is fastened or not and detect defects.

Actual photos

[Mix] Identifying product mix

Requested

Check whether the input direction of the parts is correct or whether other models are mixed in.

Actions

Defect detection by measuring the shape of a specific pattern of a part and the length of each part

Actual photos

[Position/angle] Calibrate robot working position

Requested

The position and angle of the product is suitable for transporting by robot.

Actions

Detect the angle of the shape position of a particular pattern and pass it on to the control unit to correct the position and angle

Actual photos

[Color] Illumination check

Requested

Inspect LED lighting, brightness

Actions

Check the lighting, brightness, and color using Histogram to detect defects.

Actual photos

[Barcode] Barcode recognition and location determination

Requested

Inspect Labeling & Printing Location and Barcode Information

Actions

Use the edge function to determine if the label & print location is defective and the barcode information is passed to the control unit.

Actual photos

[OCR] Character discrimination

Requested

Check to prevent products mixing by recognizing print characters

Actions

Use the OCR function to determine whether the product is defective or not

Actual photos