Feature

Structure and control suitable for medium / large cargo transportation

Extend operating time: 1 ~ 2 hours

Load carrying capacity expansion: 100kg ~ 2ton

Create on-demand for use and requirements of customers in addition to existing models

Coverage

Medium / Large cargo transportation (mountainous and remote areas)

Forest protection and Large-scale fire suppression

Seawater and Fresh water sampling

Coastal waters management

Advertising and Promotion

Areas that require long-term monitoring and detection

Specifications

| Model | ED60 | ED100 | ED200 | ED400 | |

|---|---|---|---|---|---|

| Engine | Type | 4-Stroke SOHC 2 Cylinder/4 Valves | 4-Stroke SOHC 3 Cylinder - 2 Valves/ Cyl. | 4-Stroke SOHC, 3 Cylinder, 2 Valves/Cyl. | 4-Stroke SOHC 4 Cylinder/16 Valves |

| Displacement | 350 cc (21.4 cubic inches) x 4 | 552 cc (33.7 cubic inches) x 4 | 808 cc (49.3 cubic inches) x 4 | 1,496 cc (91.4 cubic inches) x 4 | |

| Full Throttle RPM Range | 4,500-5,500 RPM | 5,000-6,000 RPM | 5,500-6,000 RPM | 5,500-6,300 RPM | |

| Rated Power | 15 HP x 4 @ 5,000 RPM | 25 HP x 4 @ 5,500 RPM | 50 HP x 4 @ 6,000 RPM | 100 HP x 4 @ 5,900 RPM | |

| Cooling System | Clean Water Cooled | Clean Water Cooled | Clean Water Cooled | Clean Water Cooled | |

| Fuel Delivery | 1 Carburetor | 3 Carburetor | Programmed Fuel Injection | Programmed Fuel Injection | |

| Fuel Tank Capacity | 5L | 15L | 30L | MicroComputer Programmed | |

| Ignition System | PGM-IG | Electric | Electric | Electric | |

| Starting System | Electric/Recoil | Through Hub | Through Hub | Through Hub | |

| Lubrication | Wet Sump | Wet Sump | Wet Sump | Wet Sump | |

| Frame | Materials | Al & Carbon | Al & Carbon | Al & Carbon | Al & Carbon |

| Size | 2.1m x 2.1m x 1.1m | 2.6m x 2.6m x 1.3m | 3.2m x 3.2m x 1.6m | 4.5m x 4.5m x 2.1m | |

| Lifting Capacity | 0.5ton ↑ | 1.0ton ↑ | 1.5ton ↑ | 2.0ton ↑ | |

| Weight | 170kg | 350kg | 520kg | 850kg | |

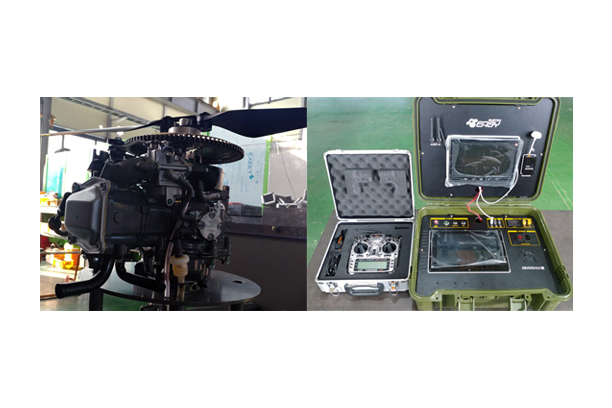

Drones Engine Base Design

- Engine compartment, control room production and design technology for dedicated engine production(engine mount, control wiring, module, etc.)

- Manufacture and Design of Engine Parts for Drones

Ability to produce optimal performance parts and various peripherals required by consumers

Obtained multi-function diagnosis equipment and instrument development technology that can diagnose dedicated engine

- Co-developed with Professional Control Company

Negotiation of joint development contract with drone control professional organization / company for domestic mass production management in future

- Developed Controller and Electric Device for Drone Engine

Securing technology for development of field control for engine running

Exclusive contract with the engine diagnostic equipment core supplier

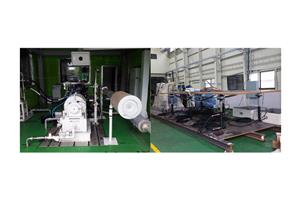

Developed cooling system / system development and secured cooling solution technology

Possess Technology

- Core Technology

Change wiring for control convenience

Manufacture of anti-vibration mount

Blade mount production

Structural improvement suitable for unmanned aerial vehicles

Construction of cooling water circulation pump

Cooling water cooler production

Start motor installation production

High temperature / pressure silicone hose application configuration

Realization Plan

Conversion of existing upright engine system optimizes for drones

Identify the fuel optimization area to secure sufficient engine output margin for cruising and acceleration in the engine speed range of 1000 ~ 3000rpm

Set items for responsiveness and time of engine control before proceeding

Integral and interlocking of the engine to change the Harness / Controller and integrate

Preparing a lightweight model by selecting the material for the external structure

Design and additional configuration of water-cooled heat exchanger enables long-term operation time

Mixed frame composition of aluminium and carbon fiber for lightening

Core Configuration

Vibration Suppression Safety of Upright Mounted Engine

Application of ECU control dron system for engine combustion control

Test drive with blade fitment and engine control

Coolant Intertooler, circulation pump manufacture and configuration