Strand Die Head(Simple 30˚ Downward Traverse Die)

The die head is designed to minimize pressure loss in continuous production.

The die head is designed for easy screen exchange and head cleaning.

The die nozzle maintains high quality at high temperature by using special steel.

When processing highly abrasive materials such as GF reinforced nylon, specially-heat-treated special steel die nozzle is used.

When processing the materials emitting corrosive gases, corrosion-proof die nozzle is used.

In addition to making the standard dies, hot-cutting-dies, UWC dies and film dies are available.

Screen changing time can be shortened by adding screen changer.

(Depending on the resin to produce a variety of items with the material can be configured, please consult with SM Platek for the material fit for the resin to be processed)

Feature

- It is easy for screen changing and head cleaning.

- Reduced screen changing time.

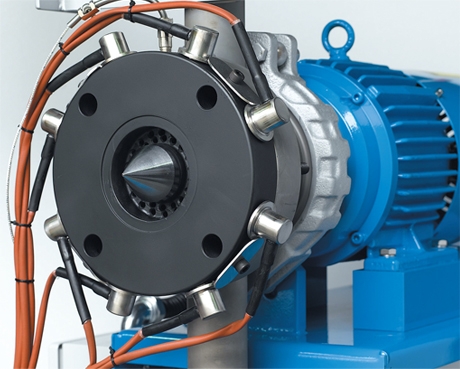

Under Water Die Head

The polymer compounded with the extruder is discharged from the nozzle on a circular die at the end of the barrel.

The polymer is cut into pellets by rotating knives and cooled in water and transferred to the centrifugal dryer.

The pallet and water transferred to the centrifugal dryer are separated into water and pellets by perforated plates are transferred to the vibrating screen by a turbo rotor blade.

The cooling water is cooled down and circulated with a heat exchanger and a pump.

The cut pellets are classified into quality products, dust and long-cuts according to their size by using a vibrating screen and will be cooled again.

The quality products are transferred to storage or packing process.

Features

- The head of the underwater cutting system can prevent oxidation of product.

- The cross section of the pellets is circular and their surface is clean and uniform.

- Nonconforming pellets produced at the die nozzle are minimized.

- Underwater cutting system is suitable for the polymers subject to little or no effect of moisture.

- Pellet size is uniform. The resins of high and low MI (Melt Index) can be processed.