+ What is Die & Mould?

Die & Mould is a tool which processes materials and produces a product using the plasticity and ductility of materials, which is called a 'Mold' or 'Container of Types.'

In a technical sense, Die& Mould is referred to as a mold that becomes a parent made of metallic materials in order to mass-produce the product of the same standard.

+ Advantages of Die & Mould

- Production of a product is shortened.

- Measurement Precision of Production goods & components is high.

- It is compatible and easy for assembly production because of the same product standard.

- The outward appearance of a product is clean and elegant.

- It's possible to produce a product which is thin in thickness and reducing a product weight .

- saving materials for a product

- it's possible to uniformize and standardize the quality of a product.

- it's possible to skip the secondary processing like assembly and welding, etc. according to a product.

- The product surface is clean, and it's possible to skip plating and painting.

- It's easy to develop a new product and to change a model.

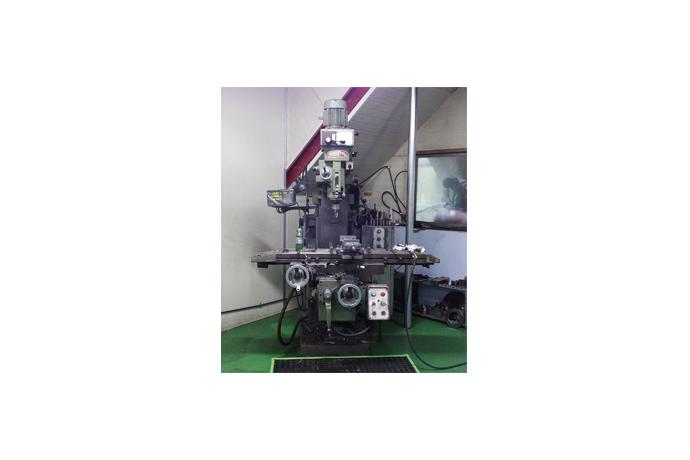

+ Sorts and Classification of Die & Mould

- Die &Mould is diversely classified according to sorts of processed products, materials, molding methods, structure, size, quantity, precision, use, etc. of Die & Mould.

- The methods of classification which are used the most can be classified plastic mould, press mould, die-cast mould and other molds according to the purpose of use and materials of moulded parts

(Plastic mould and Press mould account for about more than 70% of the domestic Die & Mould at present.)