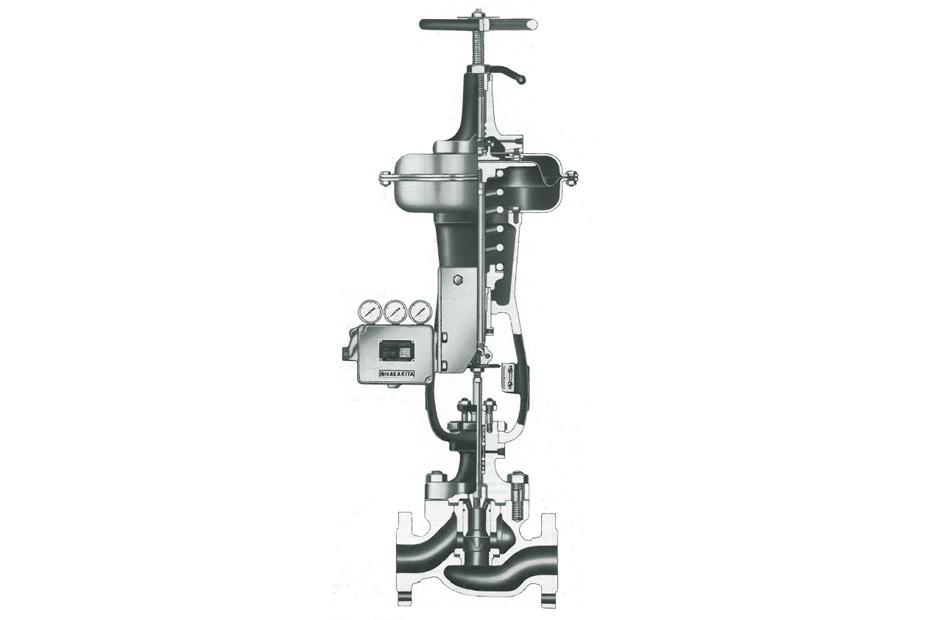

VALVE BODY ASSEMBLY

The pressure containing part consist-ing of the valve body, bonnet and trim is called the [valve body assembly]. The pressure-temper-ature rating for the materials is determined by the applicable standard. As to the type and size, the optimum selection is made accordin-ing to your [specifications].

The valve plug, seat ring, cage, guide bushing, valve stem, etc. art called the [trim], and its combination is determined according to your [specifications] including the fluid properties and pressure drop.

The [flow characteristic] which indicates the relationshop between the valve travel and the flow rate is determined by properly selecting the shape of the throttle portion consisting of the valve plug and seatring.

The gland packing is required to prevent leakage of the fluid as well as to possess low-friction property and durability. It has a vital role in the normal operation of the control valve.

DIAPHRAGM ACTUATOR

The [actuator] controls the travel of the valve, via the valve stem, by the valve, via the valve stem, by the balance between the operating air pressure applied to the dia-phragm chamber and the compres-sive force of the counter spring.

The signal (standard : 0.2 to 1.0kgf/㎠) from a pneumatic indicat-ing controller is normally guidedinto the diaphragm chamber. For further responsiveness, a positioner is installed.

When the electric signal (4 to 20 or 10 to 50 mA DC) is used, an E/P positioner is used.