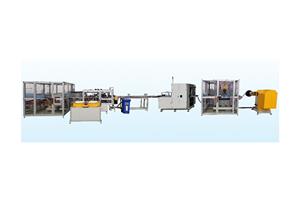

This equipment is the combination of HEPA Pleating Machine (Servo Roller Pleating) and Reciprocate Pleating Machine (Up & Down Reciprocating Blade), This pleats Non woven, Synthetic, PTFE, PP, PET, Paper, Mesh, Glass Fiber media, and more. Also, hot melt is dispensed as per preference as hot melt applicator system is installed. (Roller for pleating glass fiber is optional.)

| SPEC | DBCP-W700TSF | DBCP-W1000TSF | DBCP-W1300TSF | DBCP-W1600TSF | |

| MAX. PRODUCTION CAPACITY | 100PLEATS/MIN.: SYNTHETIC 20M/MIN.: GLASS FIBER | 100PLEATS/MIN.: SYNTHETIC 20M/MIN.: GLASS FIBER | 100PLEATS/MIN.: SYNTHETIC 20M/MIN.: GLASS FIBER | 80PLEATS/MIN.: SYNTHETIC 20M/MIN.: GLASS FIBER | |

| MAX. WIDTH OF MEDIA | 650MM | 950MM | 1250MM | 1,550MM | |

| WORKING PLEAT HEIGHT | 10~100MM: RECIPROCATE 20~100MM: HEPA PLEATING MC | 10~100MM: RECIPROCATE 20~100MM: HEPA PLEATING MC | 10~100MM: RECIPROCATE 20~100MM: HEPA PLEATING MC | 15~60MM: RECIPROCATE 25~100MM: HEPA PLEATING MC | |

HOT MELT APPLICATOR *FOAM TYPE | MAIN MOTOR | 220V*4P*SERVO MOTOR | 220V*4P*SERVO MOTOR | 220V*4P*SERVO MOTOR | 220V*4P*SERVO MOTOR |

| TANK VOLUME | 30KG*1UNIT WHIT 1 UNIT OF SUBSIDIARY TANK | 30KG*1UNIT WHIT 1 UNIT OF SUBSIDIARY TANK | 30KG*1UNIT WHIT 1 UNIT OF SUBSIDIARY TANK | 30KG*1UNIT WHIT 1 UNIT OF SUBSIDIARY TANK | |

| MELTING VOLUME | MAX. 35KG/HR | MAX. 35KG/HR | MAX. 35KG/HR | MAX. 35KG/HR | |

| HOSE | 4UNITS | 4UNITS | 8UNITS | 8UNITS | |

| AUTO GUN SOL V/V | DC24V | DC24V | DC24V | DC24V | |

| MULTI HEAD | 52SETS-OPTIONAL | 76SETS-OPTIONAL | 100SETS-OPTIONAL | 124SETS-OPTIONAL | |

| MAX. TEMP. | 230˚C | 230˚C | 230˚C | 230˚C | |

| PUMP | NITROGEN GAS | NITROGEN GAS | NITROGEN GAS | NITROGEN GAS | |

FEATURES

RECIPROCATE PLEATING MACHINE

- Field of application : Single & Multi Layer

- Working Media : Paper, Non Woven, Synthetic, PP, PE, PTFE Media

- Minimize the friction with hard chromium Coating on Pleating Blade and Heating Plate (upper & lower)

- Automatic height adjustment

- Pen Marker, W/M & Sink Type Pleating to count pleat

- ION BLOWER (To minimize static between reciprocate pleating machine and media)

- Inverter system for Production speed control

- Safety Guard System on all the doors and covers

UNWINDER & SLITTER

- Lift System for Media switching

- Media holding by 3 inch air shaft

- Media Tension Control by Powder Brake System

- Media Feeding Speed Controlled by Inverter

- Fiber Sensor to control media feeding speed

- Air Cylinder Type Slit Cutter

- Electricity: 380V/220V*60Hz*3P

- Capacity of Motor Drive: 0.40KW

- Working Media spec

Width: Max. 1,250mm(Depending on machine width)

External Diameter: Max. 1000mm

Weight: Max. 50kg

HEPA PLEATING MACHINE

- 5 patterns of hot melt dispensing

- Height adjustment by inputting value

- Individual adjustment of Hot Melt Nozzles

- Dispensing pitch: 25mm (1 inch 25.4mm – optional)

- Up & Down arrangement of hot-melt dispenser

- Media feeding control by Fiber Sensor

- Air cooling Pressure Controlling by Inverter System

- Teflon-coated idle roller

- Foam type melt application system

- Level sensor to control glue volume